Sodium hypochlorite is a widely used chemical in various industries, particularly for disinfection, bleaching, and water treatment. Its versatility and effectiveness make it an essential component in maintaining public health standards and industrial processes. However, handling sodium hypochlorite poses several challenges due to its reactive and corrosive nature. To address these challenges, specialized equipment such as sodium hypochlorite pumps are used. Walchem recognizes this need and has engineered a range of pumps tailored for sodium hypochlorite, ensuring seamless operations without compromising safety or efficiency.

Understanding Sodium Hypochlorite

Sodium hypochlorite (NaOCl) is a chemical compound commonly known as bleach. It is produced by reacting chlorine with sodium hydroxide and is typically available in a liquid form. The concentration of sodium hypochlorite solutions can vary, but it is usually around 5-15% for industrial and domestic uses. Sodium hypochlorite is a pale greenish-yellow liquid with a distinct chlorine odor. It is highly reactive and can decompose over time, especially when exposed to light, heat, or certain metals. This decomposition results in the release of chlorine gas, which is toxic and corrosive.

Challenges in Sodium Hypochlorite Handling

Handling sodium hypochlorite requires careful consideration of its chemical properties and potential hazards. The primary challenges include:

Corrosiveness: Sodium hypochlorite is highly corrosive to metals such as stainless steel, iron, and copper. This corrosion can damage equipment and lead to leaks, posing safety risks. Therefore, materials used in pumps and storage systems must be resistant to corrosion.

Reactivity: Sodium hypochlorite reacts with various substances, including acids, organic materials, and reducing agents. These reactions can produce hazardous gases such as chlorine and chloramines, necessitating controlled handling and storage conditions.

Stability: Sodium hypochlorite solutions can decompose over time, especially when exposed to sunlight, heat, or contaminants. This decomposition reduces its effectiveness as a disinfectant and can lead to the buildup of gas pressure in storage containers, creating safety hazards.

Safety: The handling of sodium hypochlorite requires strict safety measures to prevent exposure to toxic fumes and skin contact. Personal protective equipment (PPE) and proper ventilation are essential in environments where sodium hypochlorite is used.

Introducing Walchem’s Sodium Hypochlorite Pump

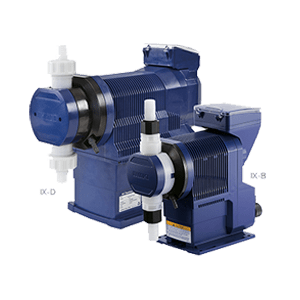

Walchem, a leading manufacturer of chemical pumps and controllers, offers specialized solutions for handling sodium hypochlorite. Walchem’s sodium hypochlorite pumps are designed to address the unique challenges posed by this chemical, ensuring safe, efficient, and reliable operation.

Design Philosophy: Walchem’s hypochlorite pumps are engineered to provide precise chemical dosing while minimizing the risks associated with sodium hypochlorite handling. The design incorporates materials that resist corrosion and withstand the reactive nature of sodium hypochlorite, ensuring long-term durability and safety. Optional degassing valves and flow sensors ensure reliability.

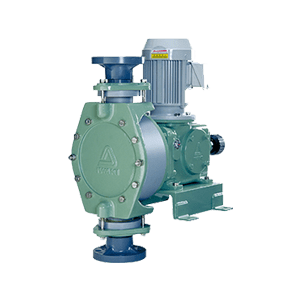

Technological Advancements: Walchem integrates advanced technologies into their pumps to enhance performance and reliability. Features such as digital controls, remote monitoring, and automated dosing systems ensure accurate and consistent delivery of sodium hypochlorite, reducing manual intervention and the potential for human error.

Commitment to Quality: Walchem is committed to producing high-quality pumps that meet stringent industry standards. Their sodium hypochlorite pumps undergo rigorous testing and quality control processes to ensure they perform reliably under challenging conditions.

Key Features of Walchem’s Sodium Hypochlorite Pump

Walchem’s sodium hypochlorite pumps are equipped with a range of features that make them suitable for demanding applications. Key features include:

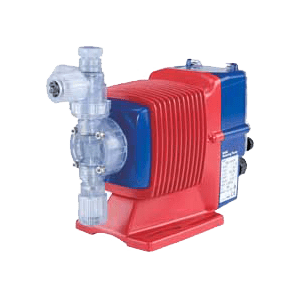

Corrosion-Resistant Materials: The pumps are constructed from materials such as PVDF (polyvinylidene fluoride), PTFE (polytetrafluoroethylene), and other high-performance plastics that resist corrosion and chemical degradation. These materials ensure that the pump components can withstand prolonged exposure to sodium hypochlorite.

Precise Dosing: Accurate dosing is critical in applications such as water treatment and disinfection. Walchem’s pumps offer precise control over chemical dosing, with digital controllers that allow for fine-tuning of flow rates. This precision helps maintain the effectiveness of sodium hypochlorite while minimizing waste.

Optional Automated Controls: Walchem’s hypochlorite pumps can be fitted with automated control systems that can monitor flow through the pump and adjust automatically if needed.

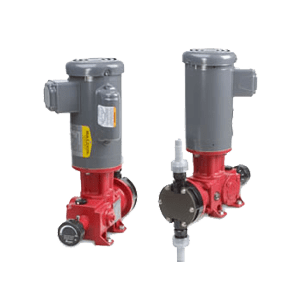

Remote Monitoring and Control: When coupled with Walchem controllers processes can be remote monitored and controlled. Operators can monitor pump performance, adjust settings, and receive alerts through a remote interface, improving operational efficiency and reducing the need for on-site supervision.

Safety Features: Safety is a top priority in the design of Walchem’s sodium hypochlorite pumps. Features such as leak detection, pressure relief valves, and automated shutdown mechanisms options help prevent accidents and ensure safe operation.

Ease of Maintenance: Walchem’s pumps are designed for ease of maintenance, with modular components that can be easily replaced or serviced. This reduces downtime and ensures that the pumps remain in optimal condition over their lifespan.

Applications of Sodium Hypochlorite Pumps

Sodium hypochlorite pumps are used in a variety of applications across different industries. Some of the key applications include:

Water Treatment: In municipal and industrial water treatment plants, sodium hypochlorite pumps are used to disinfect drinking water and treat wastewater. Accurate dosing is essential to ensure that water is free from pathogens and safe for consumption or discharge.

Swimming Pools: Sodium hypochlorite is commonly used to disinfect swimming pool water, keeping it safe for swimmers. Pumps designed for this application ensure that the correct amount of chemical is added to maintain proper chlorine levels and prevent the growth of harmful microorganisms.

Food and Beverage Industry: In the food and beverage industry, sodium hypochlorite is used for cleaning and sanitizing equipment, surfaces, and water supplies. Pumps in this setting must be able to deliver precise amounts of chemical to ensure thorough disinfection without compromising food safety.

Healthcare Facilities: Hospitals and healthcare facilities use sodium hypochlorite for disinfection purposes. Pumps ensure that surfaces, instruments, and water supplies are effectively sanitized, reducing the risk of healthcare-associated infections.

Textile and Paper Industries: Sodium hypochlorite is used as a bleaching agent in the textile and paper industries. Pumps deliver the chemical to bleaching processes, ensuring consistent and uniform bleaching results.

Chemical Manufacturing: In chemical manufacturing, sodium hypochlorite is used as a raw material or intermediate. Pumps are used to transfer and dose the chemical accurately, ensuring the efficiency and safety of production processes.

Cooling Towers: Cooling towers in industrial facilities use sodium hypochlorite to control microbial growth and prevent the buildup of biofilm. Pumps ensure that the correct amount of chemical is added to the cooling water, maintaining system efficiency and preventing contamination.

Agriculture: In agriculture, sodium hypochlorite is used for disinfecting irrigation systems and treating water supplies. Pumps ensure that the chemical is accurately dosed to protect crops and ensure safe irrigation practices.

Conclusion

Walchem’s sodium hypochlorite pumps provide a reliable and efficient solution for handling this versatile but challenging chemical. By incorporating advanced materials, precise dosing capabilities, automated controls, and robust safety features, these pumps meet the demands of various industries, from water treatment to healthcare.

Understanding the properties and challenges associated with sodium hypochlorite is crucial for selecting the right equipment, and Walchem’s pumps offer the performance and reliability needed to ensure safe and effective chemical handling. Whether used in municipal water treatment plants or industrial facilities, Walchem’s sodium hypochlorite pumps are a testament to innovation and quality in chemical handling solutions.