Sodium chloride, commonly known as table salt, is a fundamental compound with numerous industrial applications. Managing sodium chloride effectively can be quite tricky because of its properties and the necessity for measurement in different operations. Seeking a reliable pump for your sodium chloride handling needs? Look no further than Walchem’s exceptional range of solutions.

Our sodium chloride pump options are designed to meet the diverse demands of industries worldwide, ensuring seamless performance and unparalleled reliability. Explore our comprehensive range of sodium chloride pumps and accessories below, and discover the perfect solution for your application.

Understanding Sodium Chloride

Sodium chloride, commonly known as table salt (NaCl) is an ubiquitous compound found in nature and plays a role in both biological and industrial activities. It exists as a crystal, at room temperatures easily dissolves in water and creates an electrolyte solution upon dissolution. The chemical reliability and ability to dissolve of sodium chloride make it well suited for a range of uses, including food preservation and water purification purposes.

Challenges in Sodium Chloride Handling

Handling sodium chloride, despite its widespread utility, presents several critical challenges that industries must address to maintain efficiency and safety.

a. Corrosion: One of the most significant challenges in handling sodium chloride is its corrosive nature, especially in aqueous solutions. When sodium chloride dissolves in water, it forms an electrolyte solution that can cause rapid corrosion of metal surfaces. This corrosion is particularly problematic in industrial equipment such as pipes, valves, and pumps.

b. Scaling and Clogging: Another challenge is the formation of scale, which occurs when dissolved minerals precipitate out of solution and adhere to surfaces. Sodium chloride can contribute to scaling, especially in systems where temperature and concentration variations are frequent. Scaling can clog pipes, reduce the efficiency of heat exchangers, and impair the operation of pumps and valves. Addressing scaling requires regular cleaning and maintenance, as well as the use of anti-scaling agents, which add to the operational complexity and cost.

c. Accurate Dosing: Many industrial processes require precise dosing of sodium chloride to ensure optimal performance and product quality. For example, in water treatment, the correct concentration of sodium chloride is crucial for effective disinfection and desalination. Inaccurate dosing can lead to insufficient treatment, compromising water quality and safety.

d. Operational Efficiency: Ensuring operational efficiency when handling sodium chloride involves balancing several factors: maintaining equipment integrity, achieving precise dosing, and minimizing environmental impact. Traditional handling systems often struggle to meet these demands concurrently, resulting in inefficiencies and increased operational costs. Advanced solutions that can simultaneously address corrosion, scaling, and dosing accuracy are essential to overcoming these challenges and enhancing overall efficiency.

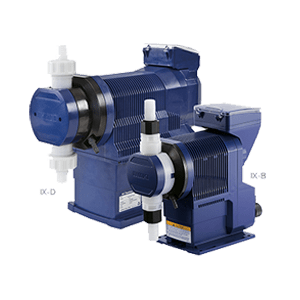

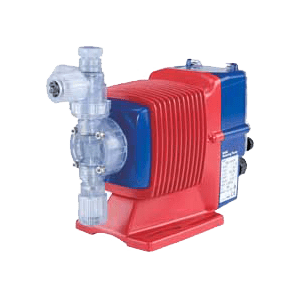

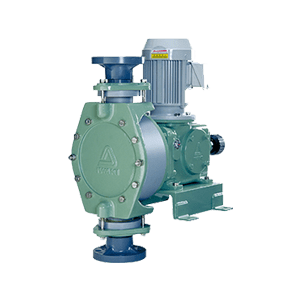

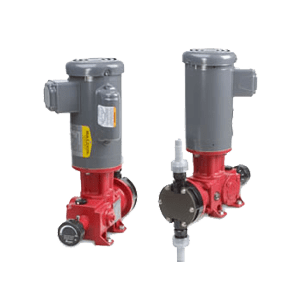

Introducing Walchem’s Sodium Chloride Pumps

Walchem, a leading provider of innovative pumping solutions, has developed state-of-the-art sodium chloride pumps designed to address these challenges effectively. Their pumps are engineered with advanced materials and cutting-edge technology to withstand the corrosive effects of sodium chloride and deliver precise dosing in various applications.

Key Features of Walchem’s Sodium Chloride Pumps

Walchem’s sodium chloride pumps boast several key features that set them apart:

Corrosion Resistance: Walchem’s pumps are constructed from corrosion-resistant materials, ensuring longevity even in harsh sodium chloride environments.

Precision Dosing: Equipped with sophisticated control systems and precision components, Walchem’s pumps deliver accurate dosing of sodium chloride, minimizing waste and optimizing process efficiency.

Modular Design: The modular design of Walchem’s pumps allows for easy customization and integration into existing systems, providing flexibility and scalability to meet diverse application requirements.

Reliability: With robust construction and rigorous testing, Walchem’s pumps offer unmatched reliability, reducing downtime and maintenance costs for end-users.

Applications of Sodium Chloride Pumps

Water Treatment: Sodium chloride is commonly used in water treatment processes for disinfection and desalination. Our pumps play a crucial role in precisely dosing sodium chloride solutions for optimal water quality and safety.

Chemical Processing: In chemical manufacturing, sodium chloride is employed in various processes, such as synthesis and separation. Walchem’s pumps enable accurate metering of sodium chloride reagents, ensuring the integrity and efficiency of chemical reactions.

Food and Beverage: Sodium chloride is a vital ingredient in food preservation, flavoring, and seasoning. Walchem’s pumps are utilized in food processing facilities to accurately inject sodium chloride solutions into products, maintaining quality and consistency.

Pharmaceutical: The pharmaceutical industry relies on precise dosing of sodium chloride in drug formulations and manufacturing processes. Walchem’s pumps meet the stringent requirements of pharmaceutical production, delivering reliable performance and compliance with regulatory standards.

Conclusion

In conclusion, Walchem’s sodium chloride pumps represent a significant advancement in the handling and application of this essential compound. By addressing the challenges associated with sodium chloride handling and offering innovative features tailored to specific industry needs, Walchem is driving efficiency, reliability, and sustainability across diverse sectors. As industries continue to evolve and demand for sodium chloride grows, the role of advanced pumping solutions will become increasingly indispensable in ensuring optimal performance and productivity.