Potassium hydroxide, also referred to as potash is a chemical widely used in various industries. With its alkaline properties it plays an important role in processes like chemical production, water treatment and pharmaceuticals. Proper handling of potassium hydroxide is essential because of its nature and potential risks involved in its usage. This is where the importance of potassium hydroxide pumps comes into the existence. These pumps are specially designed to transfer KOH solutions effectively ensuring both safety and chemical integrity.

Walchem is recognized as a key player in the field of companies that manufacture potassium hydroxide pumps. Walchem pumps are highly regarded for their dependability, efficiency and sturdy construction making them a popular choice for industries working with KOH. This detailed guide will dive into the nuances of potassium hydroxide the difficulties involved in its handling and how Walchem potassium hydroxide pumps effectively tackle these challenges. We will also examine the standout features of Walchem pumps and their diverse applications across industries.

Understanding Potassium Hydroxide

Potassium hydroxide, known by its formula KOH is a white crystalline substance that easily dissolves in water creating an alkaline solution. It acts as a base, of counteracting acids and reacting vigorously with a wide range of materials. Its reactivity lends itself to being useful, in chemical applications.

Handling potassium hydroxide requires stringent safety measures due to its corrosive nature. Contact with skin or eyes can cause severe burns, and inhalation of its dust or fumes can lead to respiratory issues. Therefore, appropriate personal protective equipment (PPE) and safety protocols are essential when working with KOH.

Challenges in Potassium Hydroxide Handling

Handling Potassium Hydroxide poses significant challenges due to its corrosive nature. Ensuring safe and efficient storage and dosing are paramount to prevent equipment degradation, environmental contamination, and safety hazards.

Corrosiveness: One of the primary challenges in handling potassium hydroxide is its corrosiveness. KOH can rapidly corrode metals, including iron, aluminum, and zinc, which poses a significant risk to standard pumping equipment. This corrosive nature necessitates the use of specialized materials and designs that can withstand prolonged exposure to KOH without degrading.

Crystallization: Potassium hydroxide solutions can crystallize at lower temperatures, leading to blockages in pumps and piping systems. This crystallization can cause operational disruptions and damage to equipment. Therefore, maintaining optimal temperature conditions and using pumps designed to handle such issues are critical.

Safety Hazards: The caustic nature of KOH means that any leaks or spills can pose serious health risks to personnel and cause environmental damage. Ensuring leak-proof and secure handling systems is essential to mitigate these risks. Additionally, emergency protocols must be in place to address any accidental exposure or spillage.

Compatibility with Other Materials: KOH’s high reactivity means it can interact with other materials used in industrial processes, potentially leading to hazardous reactions. Ensuring that all materials in contact with KOH, including pump components, seals, and tubing are compatible is crucial to prevent chemical reactions that could compromise the safety and efficiency of the process.

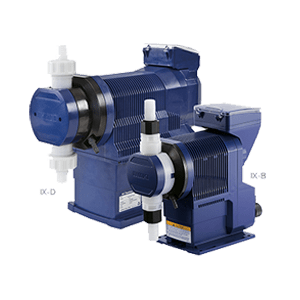

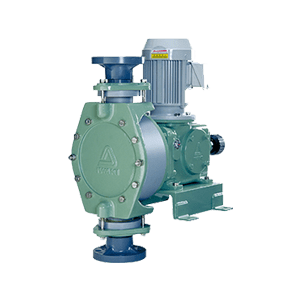

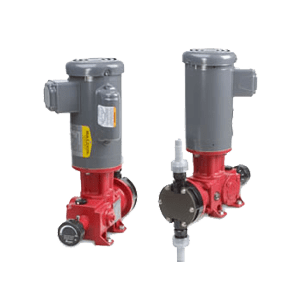

Introducing Walchem’s Potassium Hydroxide Pumps

Walchem is a leading manufacturer of innovative and reliable chemical feed and control equipment. The company specializes in designing pumps that handle a wide range of chemicals, including highly corrosive substances like potassium hydroxide. Walchem’s expertise in chemical handling and commitment to quality make its pumps a trusted choice for industries worldwide.

Walchem’s potassium hydroxide pumps are designed using advanced technology that ensures durability, efficiency, and safety. These pumps incorporate materials that resist corrosion and withstand the harsh conditions associated with handling KOH. The pumps are engineered to provide precise control over chemical dosing, ensuring consistent and accurate delivery of potassium hydroxide solutions.

Walchem prioritizes safety and efficiency in the design and manufacture of its pumps. The company’s potassium hydroxide pumps feature leak-proof designs, robust construction, and advanced control systems that minimize the risk of spills and ensure optimal performance. Walchem’s dedication to quality and innovation ensures that its pumps meet the highest industry standards.

Key Features of Walchem’s Potassium Hydroxide Pumps

Walchem’s potassium hydroxide pumps incorporate several key features that make them ideally suited for this demanding application. These features ensure optimal performance, longevity, and safety in handling potassium hydroxide.

Corrosion-Resistant Materials: Walchem’s potassium hydroxide pumps are constructed from materials specifically chosen for their resistance to corrosion. These materials include high-grade stainless steel, Hastelloy, and specialized plastics such as PTFE (Polytetrafluoroethylene) and PVDF (Polyvinylidene fluoride). These materials ensure that the pumps can withstand prolonged exposure to KOH without degrading, thus extending the lifespan of the equipment and reducing maintenance costs.

Precision Dosing: Accurate dosing is crucial in processes involving potassium hydroxide to ensure that the correct amount of chemical is delivered for the intended application. Walchem’s pumps are designed with precision dosing capabilities, allowing for fine control over the flow rate and volume of KOH being dispensed. This precision helps in maintaining process consistency and preventing overdosing or underdosing, which can lead to operational inefficiencies or safety hazards.

Ease of Maintenance: Walchem’s potassium hydroxide pumps are designed for ease of maintenance, with components that are easily accessible and replaceable. This design consideration reduces downtime and ensures that maintenance tasks can be performed quickly and efficiently. Regular maintenance is crucial for the longevity and reliability of the pumps, and Walchem’s design facilitates this process.

Applications of Potassium Hydroxide Pumps

Walchem’s potassium hydroxide pumps find application across a diverse range of industries, reflecting the widespread use of phosphoric acid in various processes. Here are some key applications:

Chemical Manufacturing: In the chemical manufacturing industry, precision and reliability are paramount. Walchem’s potassium hydroxide pumps are used in various processes, including the production of potassium compounds, saponification, and pH adjustment. The pumps’ ability to deliver accurate dosing and handle corrosive substances makes them ideal for these applications.

Water Treatment: Water treatment facilities rely on potassium hydroxide to regulate pH levels and ensure the safety and quality of water. Walchem’s pumps are used to dose KOH accurately into water systems, preventing corrosion and optimizing the effectiveness of chemical disinfectants. The robust design of these pumps ensures they can handle the harsh conditions of water treatment plants.

Pharmaceuticals: The pharmaceutical industry requires high levels of precision and hygiene. Walchem’s potassium hydroxide pumps are used in the production of medications, dietary supplements, and other pharmaceutical products. The pumps’ precision dosing capabilities and corrosion-resistant materials ensure that they meet the stringent standards of the pharmaceutical industry.

Food Industry: In the food industry, potassium hydroxide is used in various processes, including food preservation and the production of low-sodium products. Walchem’s pumps are employed to accurately dispense KOH, ensuring the consistency and safety of food products. The pumps’ ability to handle corrosive substances make them a valuable asset in food processing.

Industrial Cleaning: Potassium hydroxide is a common ingredient in industrial cleaning solutions due to its strong alkaline properties. Walchem’s pumps are used to dispense KOH in cleaning applications, providing effective removal of grease, oils, and other contaminants. The pumps’ durability and resistance to corrosion ensure reliable performance in demanding cleaning environments.

Laboratory Applications: In research and laboratory settings, precision and reliability are critical. Walchem’s potassium hydroxide pumps are used in various laboratory applications, including chemical synthesis, pH adjustment, and titration. The pumps’ ability to deliver precise and controlled amounts of KOH makes them indispensable tools in scientific research.

Agricultural Applications: In agriculture, potassium hydroxide is used as a fertilizer additive and for pH control in soil and water. Walchem’s pumps are employed to dispense KOH solutions in agricultural applications, ensuring the correct amount is applied for optimal crop growth. The pumps’ rugged construction and precise dosing capabilities make them suitable for the demands of agricultural use.

Conclusion

Potassium hydroxide is a versatile and essential chemical used in various industries, from chemical manufacturing to water treatment and pharmaceuticals. However, its corrosive nature and the potential hazards associated with its handling necessitate the use of specialized equipment, such as potassium hydroxide pumps. Walchem, a leader in the industry, provides reliable, efficient, and safe pumps designed specifically for handling KOH.

Walchem’s potassium hydroxide pumps offer numerous features that address the challenges of handling KOH, including corrosion-resistant materials, precision dosing, advanced control systems, and ease of maintenance. These features ensure that the pumps deliver consistent performance, enhance safety, and reduce maintenance costs.