Phosphoric acid (H₃PO₄) is a crucial industrial chemical, pivotal in various applications ranging from agriculture to food processing. The need to handle and dose this highly corrosive substance safely and efficiently has led to the requirement of specialized equipment, notably phosphoric acid pumps. Among the leading manufacturers in this field is Walchem, renowned for its robust and reliable pump designs tailored for phosphoric acid handling.

Understanding Phosphoric Acid

Phosphoric acid is a mineral (inorganic) acid having the chemical formula H₃PO₄. It is a triprotic acid, meaning it has three hydrogen atoms that can dissociate, making it capable of forming three different salts. Its ability to release protons in a stepwise manner is a fundamental property that dictates its behavior in various chemical processes.

Properties of Phosphoric Acid

Physical Properties:

- Appearance: Colorless, odorless, and crystalline in its pure form.

- Solubility: Highly soluble in water, forming a viscous solution.

- Boiling and Melting Points: Boiling point of approximately 158°C and melting point at around 42.35°C.

Chemical Properties::

- Acidity: Moderately strong acid with a first dissociation constant (Ka₁) of 7.5 x 10⁻³.

- Reactivity: Reacts with bases to form phosphate salts and with metals to produce hydrogen gas.

- Dehydration: At high temperatures, it can lose water to form pyrophosphoric acid (H₄P₂O₇) and metaphosphoric acid (HPO₃).

Challenges in Phosphoric Acid Handling

Handling phosphoric acid poses significant challenges due to its corrosive nature and reactivity. Ensuring safe and efficient storage and dosing is paramount to prevent equipment degradation, environmental contamination, and safety hazards.

Corrosive Nature: Phosphoric acid is highly corrosive to metals, particularly ferrous alloys. Prolonged exposure can lead to severe material degradation, compromising the integrity of storage tanks, pipelines, and pumps. Therefore, materials used in equipment handling phosphoric acid must be highly resistant to corrosion.

Viscosity and Temperature Sensitivity: Phosphoric acid’s viscosity can vary significantly with concentration and temperature. High viscosity can impede flow, requiring more robust pumping systems to maintain efficiency. Additionally, temperature fluctuations can affect the acid’s physical state and reactivity, necessitating careful thermal management during storage and dosing.

Environmental and Safety Concerns: Spills and leaks of phosphoric acid pose environmental hazards, contaminating soil and water bodies. The acid’s corrosive nature can cause severe injuries upon contact with skin or eyes, and inhalation of vapors can irritate the respiratory tract. Strict regulatory compliance and robust safety protocols are essential to mitigate these risks.

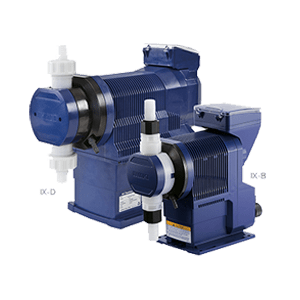

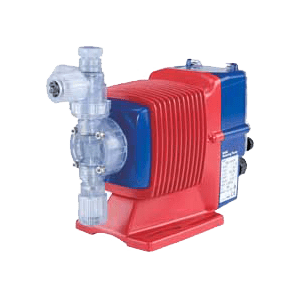

Introducing Walchem’s Phosphoric Acid Industrial Pumps

Walchem, a prominent name in fluid handling solutions, has developed a range of pumps specifically designed to handle the unique challenges posed by phosphoric acid. Our chemical pumps for phosphoric acid are engineered to offer exceptional durability, reliability, and efficiency, ensuring safe and effective acid transfer in various industrial settings.

With decades of experience in the field, Walchem leverages advanced materials and innovative design principles to create pumps that withstand the harsh conditions associated with phosphoric acid handling. Our commitment to quality and customer satisfaction has established us as a trusted partner for industries worldwide.

Key Features of Walchem’s Phosphoric Acid Pumps

Walchem’s phosphoric acid pumps incorporate several key features that make them ideally suited for this demanding application. These features ensure optimal performance, longevity, and safety in handling phosphoric acid.

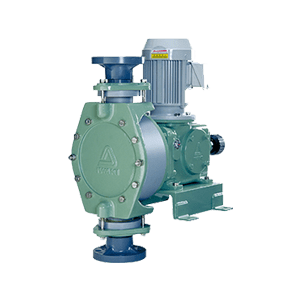

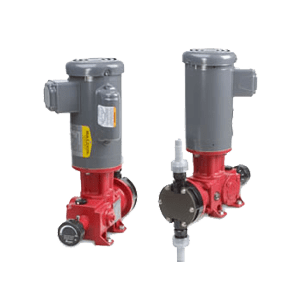

Variable Speed Control: To accommodate the varying viscosity and flow requirements of phosphoric acid, our pumps often incorporate variable speed drives. This allows for precise control over pump operation, ensuring efficient and consistent fluid transfer regardless of changing conditions.

Robust Construction: Our chemical pumps for phosphoric acid are designed to withstand the harsh operational environments typically encountered in industrial settings. Features such as heavy-duty bearings, reinforced housings, and high-torque motors ensure reliable performance even under demanding conditions.

Easy Maintenance and Serviceability: Ease of maintenance is a critical consideration in pump design. Our phosphoric acid industrial pumps are engineered for straightforward disassembly and reassembly, facilitating routine maintenance and minimizing downtime. Accessible components and modular designs further enhance serviceability.

Applications of Phosphoric Acid Pumps

Walchem phosphoric acid pumps find application across a diverse range of industries, reflecting the widespread use of phosphoric acid in various processes. Here are some key applications:

Agriculture and Fertilizer Production: Phosphoric acid is a key ingredient in the production of fertilizers, essential for modern agriculture. Phosphoric acid pumps facilitate the efficient transfer in fertilizer manufacturing plants, ensuring precise dosing and mixing.

Food and Beverage Industry: In the food and beverage industry, phosphoric acid is used as an acidulant to regulate pH and enhance flavor. Phosphoric acid pumps are employed to handle the acid in food processing facilities, ensuring safe and contamination-free transfer.

Water Treatment: Phosphoric acid is used in water treatment processes to prevent pipe corrosion and scale formation. Walchem pumps enable the accurate dosing of phosphoric acid in water treatment plants, contributing to the maintenance of clean and safe water supplies.

Chemical Manufacturing: In chemical manufacturing, phosphoric acid serves as a catalyst and reactant in various processes. Walchem’s robust and reliable pumps are used to dose phosphoric acid in chemical plants, ensuring process efficiency and safety.

Pharmaceuticals: The pharmaceutical industry uses phosphoric acid in the synthesis of certain drugs and as an excipient in formulations. Walchem pumps ensure the precise and safe handling of phosphoric acid in pharmaceutical manufacturing, maintaining product quality and safety standards.

Metal Treatment: Phosphoric acid is used in metal treatment processes, such as rust removal and phosphating, to prepare metal surfaces for painting and coating. Walchem pumps facilitate the application of phosphoric acid in metal treatment facilities, ensuring consistent and effective surface preparation.

Conclusion

Handling phosphoric acid requires specialized equipment designed to withstand its corrosive nature and ensure safe and efficient transfer. Walchem phosphoric acid pumps exemplify excellence in this field, offering a range of features that address the unique challenges associated with phosphoric acid handling. From corrosion-resistant materials to advanced control systems, these pumps are engineered to deliver reliable performance across various industries. Whether in agriculture, food processing, water treatment, or chemical manufacturing, Walchem phosphoric acid pumps play a vital role in facilitating the safe and efficient use of this essential chemical.