Nitric acid, a highly corrosive and reactive chemical, is a key component in various industrial processes, including fertilizer production, explosives manufacturing, and metal processing. Handling and transferring this powerful acid require specialized equipment designed to withstand its aggressive nature. Nitric acid pumps are crucial in safely and efficiently moving nitric acid in industrial settings, ensuring both operational efficiency and worker safety.

As industries continue to evolve and demand more efficient and safer handling of hazardous chemicals, the role of specialized pumps like those from Walchem will become increasingly important. Investing in high-quality nitric acid pumps not only enhances operational efficiency but also ensures compliance with safety standards, ultimately contributing to the overall success and sustainability of industrial processes.

Understanding Nitric Acid

Nitric acid (HNO3) is a highly corrosive mineral acid used extensively in various industries. It is a colorless, fuming liquid in its concentrated form and is known for its powerful oxidizing properties. The chemical is a key ingredient in the production of fertilizers, explosives, and in processes such as metal etching and cleaning.

Chemical Properties:

- Molecular Formula: HNO3

- Molar Mass: 63.01 g/mol

- Density: 1.51 g/cm³

- Melting Point: -42 °C

- Boiling Point: 83 °C

Nitric acid is highly reactive, especially with metals, and can cause severe burns upon contact with skin. Its handling requires stringent safety measures and specialized equipment, particularly for dosing and pumping operations.

Challenges in Nitric Acid Handling

Handling nitric acid involves several critical challenges due to its corrosive and reactive nature. The key challenges include:

Corrosion

Material Compatibility: Nitric acid can rapidly corrode metals and degrade non-resistant materials. Equipment must be made from or lined with materials that can withstand prolonged exposure to the acid.

Pump Longevity: Continuous exposure to nitric acid can reduce the lifespan of pumps. Materials such as PTFE (polytetrafluoroethylene) and PVDF (polyvinylidene fluoride) are often used to enhance resistance.

Safety Concerns

Human Safety: Direct contact with nitric acid can cause severe injuries. Thus, leak-proof and robust handling systems are essential.

Environmental Safety: Spillage or leaks can result in significant environmental damage. Systems must be designed to contain and neutralize any accidental releases.

Operational Efficiency

Flow Control: Precise control over the flow rate of nitric acid is necessary to ensure process efficiency and safety.

Maintenance: Frequent maintenance needs due to corrosion can interrupt operations and increase costs.

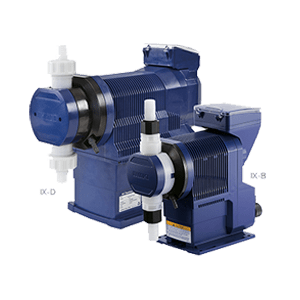

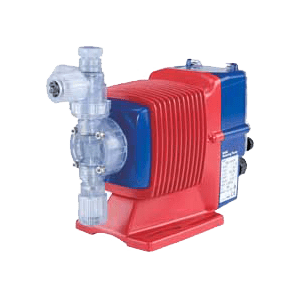

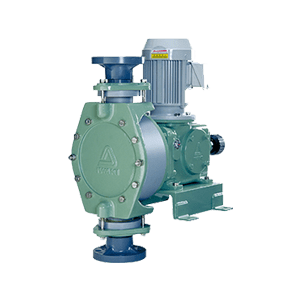

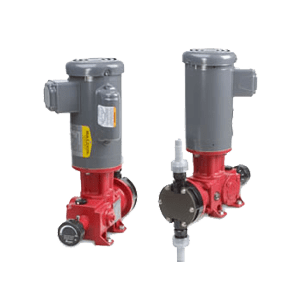

Introducing Walchem’s Nitric Acid Pumps

Walchem, a leading manufacturer of industrial pumps, has developed a range of nitric acid pumps, designed to address these challenges. Walchem’s expertise in chemical pump technology is reflected in their robust designs and innovative features that ensure safe and efficient nitric acid handling.

Key Features of Walchem’s Nitric Acid Pumps

Walchem’s nitric acid pumps incorporate several key features that make them suitable for handling this highly corrosive substance:

Material Construction: Walchem pumps are constructed using materials such as PTFE, PVDF, and other fluoropolymers that offer excellent resistance to nitric acid. This ensures durability and long service life.

High Precision: Walchem pumps are designed to provide precise flow control, which is crucial for maintaining the integrity of industrial processes involving nitric acid.

Variable Flow Rates: The pumps can be adjusted to deliver a wide range of flow rates, catering to different application requirements.

Accessible Components: Key components are designed for easy access, making routine inspections and maintenance tasks straightforward.

Applications of Nitric Acid Pumps

Walchem’s nitric acid pumps are versatile and find applications across various industries. Here are some of the primary uses:

Chemical Manufacturing: Nitric acid is a key ingredient in the production of ammonium nitrate and other fertilizers. Efficient pumping systems are essential for handling the acid safely and maintaining continuous production.

Metal Processing: Nitric acid is used for etching and cleaning metals, especially in the electronics and aerospace industries. Pumps need to handle the acid efficiently to ensure high-quality surface finishes and meet strict industry standards.

Water Treatment: Nitric acid is used in water treatment plants to adjust pH levels. Walchem pumps enable precise dosing, ensuring the correct amount of acid is introduced to achieve the desired pH levels.

Pharmaceuticals: In pharmaceutical manufacturing, nitric acid is used in various synthesis processes. Accurate and reliable pumps are essential to maintain the integrity of chemical reactions and ensure product quality.

Research and Development: In research settings, small-scale but precise handling of nitric acid is required for experiments and chemical synthesis. Walchem’s pumps provide the necessary precision and safety features.

Food and Beverage: Nitric acid is sometimes used for sanitization and cleaning processes in the food and beverage industry. Pumps must be designed to ensure that they do not contaminate products while handling the acid safely.

Conclusion

In conclusion, nitric acid pumps are a critical component in various industrial processes due to the highly corrosive and hazardous nature of nitric acid. The challenges associated with handling nitric acid, such as corrosion, safety, and operational efficiency, necessitate the use of specialized equipment. Walchem’s nitric acid pumps stand out in this field, offering innovative solutions that enhance safety, durability, and performance.

The advanced materials and design features of Walchem pumps, including corrosion-resistant construction and precise flow control, make them ideal for a wide range of applications. From chemical manufacturing and metal processing to water treatment and pharmaceuticals, these pumps provide reliable and efficient handling of nitric acid, ensuring both safety and process integrity.