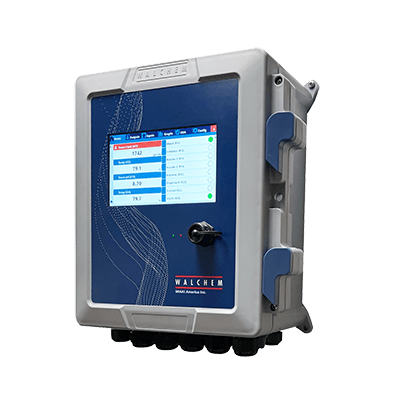

Intuition-9

Winery Application

Intuition-9 controller reduces or eliminates fines from wastewater district when installed properly.

Customer | Wineries

APPLICATION

The US wine market has increased dramatically over the last 10 years and has now become the number one provider of wine in the US. This boom in consumption within the US and abroad has fueled the demand for more wineries and higher production from existing wineries.

PROBLEM

The problem lies with the waste treatment from the grape crush in the wine making process. In the early stages, the industry was allowed to perform minimal treatment and to discharge into the sanitary sewers. The problem came with the increased production and the timing of the grape crush that normally occurs within a couple of months during the year. Grapes have a low pH and also produce high COD (chemical oxygen demand) and BOD (biological oxygen demand) from the grape skins. This can cause problems with municipal waste treatment plants by killing the bacteria necessary for treatment.

A number of counties in Northern California have begun requiring wine processors to post cash bonds for permits. In Sonoma County, the cash bond is $100,000 and is held for one year, then returned less the fines imposed. The new regulations and subsequent fines are causing wine processors to construct pretreatment systems or holding ponds for their waste.

If the INT-9 controller is being used on a waste treatment pond a dissolved oxygen sensor will be required and should be used in conjunction with and aeration system. Typically these ponds will be seeded with bacteria and nutrients and may require chemical pumps to replenish these levels.

The INT-9 controller can also handle the irrigation water to the vineyards. This may consist of fertigation and pH adjustment particularly if drip irrigation is employed. The emitters are prone to clogging in high pH and alkaline waters. The fertilizer concentration can be controlled by conductivity, as there are charts from the fertilizer manufacturers that give conductivity vs nitrogen (N), phosphorous (P) and potassium (K).

SOLUTION

The INT-9 controller has the available inputs to control this process through direct sensors and 4 to 20 milliamp inputs for other analytical measurements. A typical installation would consist of:

(2) pH sensors- one for the direct effluent from the crush treatment and one prior to the sanitary sewer

(1) Turbidity monitor-to monitor suspended solids

(2) Ultrasonic tank level monitors-one for caustic and one for a polymer

(2) Chemical pumps-one for caustic and one for a polymer

(2) Chemical pump feed verification

(1) Flow meter to monitor effluent flow

Other areas for treatment may include ozonation as chlorine causes an “off” taste to wine if the juice or wine contacts it directly.

BENEFITS OF USING INT-9 CONTROLLERS:

• Reduced or no fines from wastewater district when installed properly

• Benefits of using INT-9 controllers Reliable control of all parameters

• Instantaneous alarming via e-mail and cell phone text messaging

• Data logging for proof of compliance and efficiency monitoring

• Low-cost of system.

WHERE TO FIND SIMILAR ACCOUNTS

Local wine growers and production associations

Suppliers of equipment to growers and processors

Suppliers of chemicals to growers and processors

Agricultural suppliers

Talk to wastewater district to see who has been fined

Talk to the wineries and discuss their current treatment.