In the field of operations ensuring precision, reliability and safety is crucial. Hydrogen peroxide stands out due to its versatility in applications such, as disinfection and oxidation. To tackle the challenges Walchem has introduced its cutting-edge Hydrogen Peroxide Pumps.

Understanding Hydrogen Peroxide

Before we dive into the details of Walchem’s hydrogen peroxide pumps it’s important to understand the role of hydrogen peroxide. Known by its chemical formula H₂O₂, hydrogen peroxide is a scentless liquid known for its oxidizing properties. It is widely utilized as a disinfectant, whitening agent and oxidizer across sectors such, as wastewater treatment, textile production, paper manufacturing and the electronics industry. However, its strength and reactivity require careful handling and precise dosing to guarantee safety and effectiveness.

Challenges in Hydrogen Peroxide Handling

While hydrogen peroxide offers numerous benefits in industrial applications, its handling poses several challenges. One of the primary challenges is achieving accurate dosing and control. Improper dosing can lead to inefficiencies in processes or, worse, pose safety risks.

Additionally, hydrogen peroxide’s reactivity with certain materials necessitates specialized equipment to prevent corrosion and ensure longevity. Moreover, ensuring consistent performance and minimizing downtime are crucial factors in industrial operations. Addressing these challenges requires innovative solutions tailored to the unique demands of hydrogen peroxide handling.

Introducing Walchem Hydrogen Peroxide Pumps

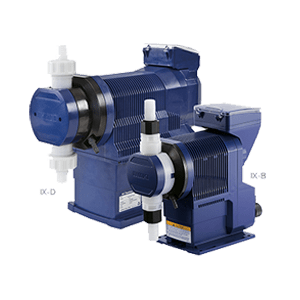

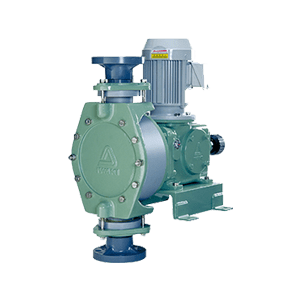

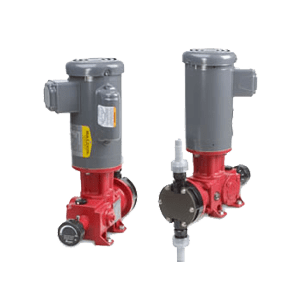

Walchem, a trusted name in industrial fluid handling solutions, steps up to the challenge with its state-of-the-art Hydrogen Peroxide Pumps. Engineered with precision and reliability in mind, Walchem pumps are designed to streamline hydrogen peroxide handling in industrial processes. These pumps incorporate cutting-edge technology, robust construction, and user-friendly features to deliver exceptional performance across various applications.

Key Features of Walchem Hydrogen Peroxide Pumps

Precision Dispensing: Walchem pumps are engineered to provide precise dosing of hydrogen peroxide, ensuring accuracy in chemical processes. Advanced pump design and control mechanisms enable consistent and uniform dispensing, critical for achieving desired outcomes in industrial applications.

Durability and Reliability: Constructed from high-quality materials, Walchem pumps exhibit exceptional durability, capable of withstanding harsh industrial environments. Rigorous testing and quality assurance measures ensure reliable performance, minimizing the risk of downtime and maximizing productivity.

Versatility: Walchem Hydrogen Peroxide Pumps are versatile, accommodating a wide range of hydrogen peroxide concentrations and viscosities. Their adaptability makes them suitable for diverse applications across industries, from water treatment to chemical processing and beyond.

Safety: Safety is paramount in industrial settings, and Walchem prioritizes it with built-in safety features in its pumps. These features mitigate risks associated with hydrogen peroxide handling, safeguarding personnel, and equipment.

Easy Maintenance: Walchem pumps are designed for simplicity and ease of maintenance, minimizing downtime, and reducing overall operational costs. User-friendly interfaces and accessible components facilitate routine maintenance tasks, ensuring optimal pump performance.

Applications of Walchem Hydrogen Peroxide Pumps

The versatility and reliability of Walchem Hydrogen Peroxide Pumps make them indispensable across a spectrum of industrial applications:

Water Treatment: In water treatment plants, Walchem pumps facilitate the precise dosing of hydrogen peroxide for disinfection and oxidation processes. They help maintain water quality standards while optimizing operational efficiency and cost-effectiveness.

Chemical Manufacturing: Walchem pumps play a crucial role in chemical manufacturing processes, where precise chemical dosing is essential for product quality and consistency. From batch processing to continuous production, these pumps ensure accurate dispensing of hydrogen peroxide, contributing to the efficiency and reliability of operations.

Pulp and Paper Production: The pulp and paper industry relies on hydrogen peroxide for bleaching and deinking processes. Walchem Hydrogen Peroxide Pumps enable precise control over hydrogen peroxide dosage, resulting in improved pulp quality, reduced environmental impact, and enhanced process efficiency.

Textile Industry: In textile bleaching and dyeing operations, Walchem pumps offer unparalleled precision in hydrogen peroxide dosing, ensuring uniform coloration and quality finishes. Their reliability and performance contribute to the optimization of textile manufacturing processes, enhancing productivity and reducing waste.

Electronics Manufacturing: Hydrogen peroxide finds applications in electronics manufacturing for surface cleaning and etching processes. With Walchem Hydrogen Peroxide Pumps, electronics manufacturers can achieve precise control over chemical concentrations, leading to superior cleaning and etching results while minimizing material waste and environmental impact.

Walchem Hydrogen Peroxide Pumps represent a paradigm shift in industrial fluid handling, offering unmatched precision, reliability, and safety in hydrogen peroxide dispensing. With their advanced features, robust construction, and versatility, these pumps empower industries to optimize processes, improve product quality, and achieve operational excellence.

Whether in water treatment, chemical manufacturing, pulp and paper production, textiles, electronics, or other sectors, Walchem pumps redefine the standards of hydrogen peroxide handling, driving efficiency and innovation across industries. Experience the transformative power of Walchem Hydrogen Peroxide Pumps and elevate your industrial processes to new heights of performance and sustainability.