Hydrochloric acid also known as HCL or muriatic acid, stands out as a crucial component in various processes. Handling it efficiently and safely is non-negotiable. It is a highly corrosive, reactive chemical that finds extensive applications across industries ranging from water treatment to metal processing. HCL handling demands meticulous attention to detail and top-tier equipment.

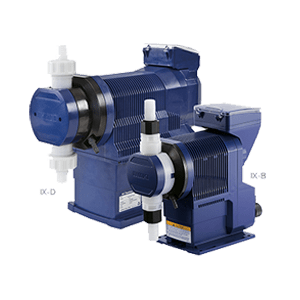

Walchem recognizes this need and has engineered a range of pumps tailored for hydrochloric acid dosing, ensuring seamless operations without compromising safety or efficiency.

Understanding Hydrochloric Acid

Before we dive into the details of Walchem’s hydrochloric acid pumps it’s important to understand the role of hydrochloric acid, in industrial settings. Hydrochloric acid is a highly corrosive and versatile chemical compound, serves as a cornerstone in numerous industrial processes, ranging from water treatment to metal processing. Understanding its properties is essential for ensuring safe and efficient operations.

Hydrochloric acid, often referred to as muriatic acid in its industrial form, is a colorless, highly acidic solution of hydrogen chloride (HCl) gas dissolved in water. With a pungent odor and strong acidity, it is classified as a strong mineral acid, capable of corroding various materials upon contact. Its chemical formula, HCl, signifies one hydrogen atom bonded to one chlorine atom, giving it a molecular weight of approximately 36.46 g/mol. Understanding the chemical composition and reactivity of hydrochloric acid is crucial when designing equipment like pumps, ensuring compatibility with materials and safety in handling.

Challenges in Hydrochloric Acid Handling

Despite its widespread industrial use, handling hydrochloric acid presents unique challenges that require careful consideration and specialized equipment like Walchem’s Hydrochloric Acid Pumps. From its corrosive nature to safety concerns and environmental impact, addressing these challenges is essential for ensuring smooth and efficient operations in chemical handling processes.

Corrosion and Material Compatibility: One of the primary challenges in hydrochloric acid handling is its corrosive nature, which can degrade equipment and infrastructure over time. Selecting materials that are resistant to hydrochloric acid corrosion is crucial for ensuring the longevity and integrity of storage tanks, piping systems, and pumping equipment. Walchem’s Hydrochloric Acid Pumps address this challenge by utilizing corrosion-resistant materials in its construction, minimizing the risk of degradation and equipment failure.

Safety Risks and Personnel Protection: Hydrochloric acid poses significant safety risks to personnel involved in its handling, including skin and eye irritation, respiratory problems, and potential chemical burns. Implementing stringent safety protocols and providing appropriate personal protective equipment (PPE) is essential for minimizing the risk of accidents and injuries. Walchem’s Hydrochloric Acid Pumps are designed with built-in safety features, such as leak detection and emergency shutdown mechanisms on most models, to mitigate these risks and safeguard personnel throughout the handling process.

Environmental Impact and Containment: Spills or releases of hydrochloric acid can have severe environmental consequences, contaminating soil, water bodies, and air quality. Implementing effective containment measures and spill response protocols is essential for minimizing environmental impact and preventing harm to ecosystems and human health. Walchem’s Hydrochloric Acid Pumps facilitate safe and controlled chemical transfer, reducing the likelihood of spills and releases during handling operations.

Introducing Walchem’s HCL Pumps

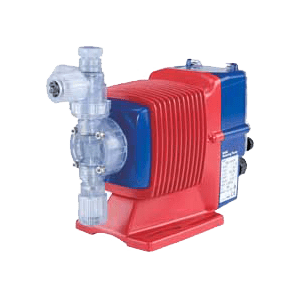

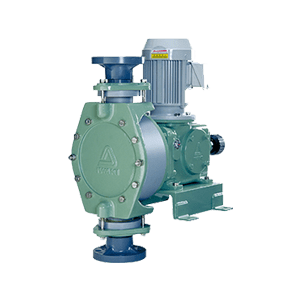

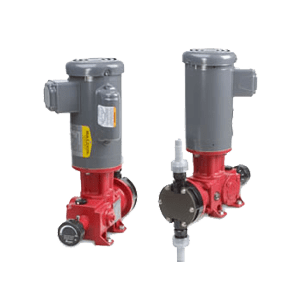

Walchem, a trusted name in industrial fluid handling solutions, steps up to the challenge with its state-of-the-art Hydrochloric Acid Pumps. Engineered with precision and reliability in mind, Walchem pumps are designed to streamline Hydrochloric Acid handling in industrial processes. These pumps incorporate cutting-edge technology, robust construction, and user-friendly features to deliver exceptional performance across various applications. Our HCL pumps are built with non-metallic materials and corrosive resistant elastomers.

Key Features of Walchem’s Hydrochloric Pump

Walchem’s Hydrochloric Pumps set the benchmark for excellence in chemical handling technology, offering a range of innovative features designed to optimize performance, safety, and reliability. From precision control to robust safety mechanisms, these key features distinguish Walchem’s pump solution as the preferred choice for hydrochloric acid handling applications.

Chemical Compatibility: Walchem’s Hydrochloric Pumps are constructed from materials specifically selected for their superior chemical resistance, ensuring compatibility with hydrochloric acid and other corrosive substances. Engineered using corrosion-resistant materials and specialized polymers, the pump’s components withstand the harsh operating conditions associated with chemical handling, minimizing the risk of degradation and equipment failure.

Precision Flow Control: Achieving precise flow control is essential for optimizing chemical usage and maintaining process integrity. Walchem’s Hydrochloric Acid Pumps are equipped with advanced control features, including variable speed, enabling precise adjustment of flow rates according to operational requirements. This level of control ensures consistent performance and minimizes chemical waste, enhancing operational efficiency and productivity.

Safety Mechanisms: Safety is paramount in chemical handling operations, and Walchem’s Hydrochloric Acid Pumps are engineered with multiple layers of protection to mitigate risks and safeguard personnel, equipment, and the environment. On most models integrated safety mechanisms, such as leak detection, overpressure protection, and emergency shutdown features, ensure safe and reliable operation, even in the event of unforeseen circumstances or equipment failure.

Durability and Reliability: Built to the highest standards of quality and craftsmanship, Walchem’s Hydrochloric Acid Pumps deliver unparalleled durability and reliability in the most demanding industrial environments. Robust construction, coupled with advanced engineering design, ensures long-term performance and minimal maintenance requirements, minimizing downtime and maximizing operational uptime.

Applications of Hydrochloric / Muriatic Acid Pumps

Hydrochloric acid pumps play a pivotal role across a wide range of industrial applications, where precision, reliability, and safety are paramount. From water treatment to metal processing, the versatility of hydrochloric acid makes it indispensable in numerous processes.

Walchem’s Hydrochloric Acid Pumps are specifically engineered to meet the unique demands of these applications, offering unparalleled performance and efficiency. Here’s how hydrochloric acid pumps, including Walchem’s innovative solution, are utilized in various industries:

Water Treatment: In water treatment facilities, hydrochloric acid is commonly used for pH adjustment and disinfection. Walchem’s Hydrochloric Acid Pumps facilitate precise dosing of hydrochloric acid into water treatment systems, ensuring optimal pH levels and effective disinfection to meet regulatory standards and maintain water quality.

Metal Pickling and Surface Treatment: Hydrochloric acid is a key component in metal pickling and surface treatment processes, where it is used to remove surface oxides, scale, and contaminants from metal surfaces prior to further treatment or coating. Walchem’s Hydrochloric Acid Pumps enable controlled and uniform application of hydrochloric acid, facilitating efficient and thorough metal cleaning and preparation.

Chemical Synthesis and Laboratory Procedures: Hydrochloric acid serves as a catalyst and reagent in various chemical synthesis and laboratory procedures, where precise handling and dosing are critical. Walchem’s Hydrochloric Acid Pumps provide accurate flow control and delivery of hydrochloric acid, ensuring reproducible results and optimal reaction conditions in chemical synthesis and laboratory experiments.

Food and Beverage Processing: In the food and beverage industry, hydrochloric acid is used for pH adjustment, cleaning, and sanitization of equipment and processing lines. Walchem’s Hydrochloric Acid Pumps enable precise dosing of hydrochloric acid solutions for pH control, ensuring product quality and safety compliance in food and beverage processing operations.

Textile and Leather Industries: Hydrochloric acid plays a vital role in the textile and leather industries for processes such as desizing, bleaching, and dyeing. Walchem’s Hydrochloric Acid Pumps provide reliable and efficient delivery of hydrochloric acid solutions, facilitating uniform treatment of textiles and leather materials to achieve desired color, texture, and finish.

Oil and Gas Production: In the oil and gas industry, hydrochloric acid is used for well stimulation, scale removal, and acidizing operations. Walchem’s Hydrochloric Acid Pumps enable accurate and controlled injection of hydrochloric acid into oil and gas wells, helping to optimize production rates and enhance reservoir performance.

Pharmaceutical and Chemical Manufacturing: Hydrochloric acid is utilized in pharmaceutical and chemical manufacturing processes for synthesis, purification, and pH adjustment. Walchem’s Hydrochloric Acid Pumps ensure precise dosing of hydrochloric acid solutions, facilitating efficient and reproducible production of pharmaceuticals, specialty chemicals, and fine chemicals.