Flocculants play an important role in water treatment by joining particles to create larger clusters which make it easier to remove them from the water. The incorporation of flocculants in water treatment is essential to ensure that water, whether used for purposes municipal supply or wastewater treatment meets the quality standards.

Understanding Flocculants in Water Treatment

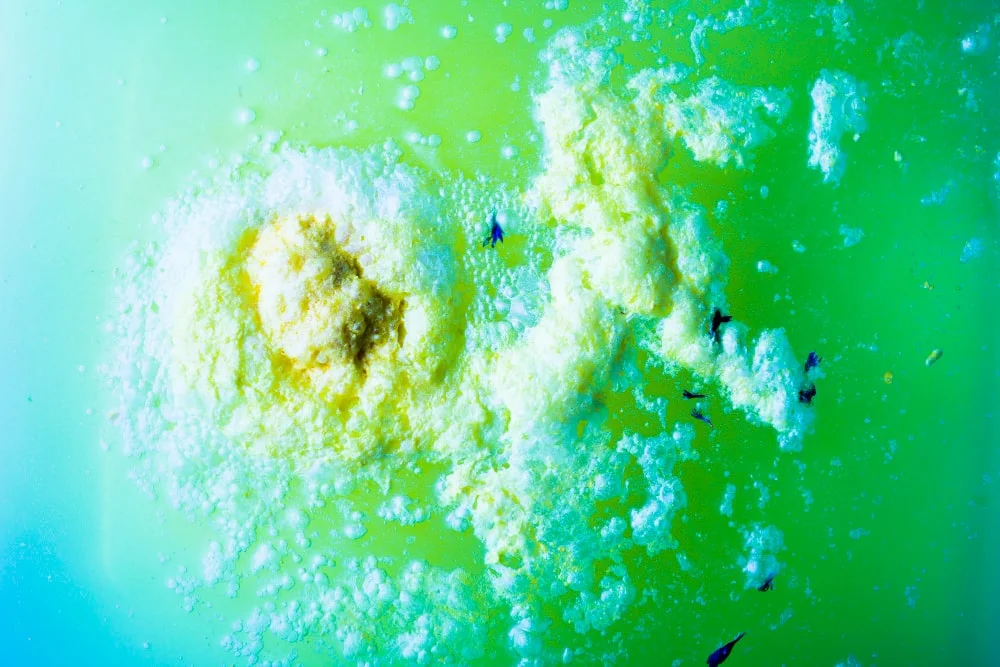

Flocculants operate by neutralizing out the charges in suspended particles, which enable them to cluster and create flocs. These flocs can be eliminated through sedimentation, flotation or filtration. The primary varieties of flocculants employed in water treatment include:

- Inorganic Flocculants: Usually metal salts, like alum (aluminum sulfate) or ferric chloride are commonly used.

- Organic Flocculants: Polymers, like polyacrylamides, which may be synthetic or occur naturally.

- Hybrid Flocculants: Optimizing performance by combining organic compounds.

Choosing the appropriate flocculant relies on the unique qualities of the water undergoing treatment such, as the kind and number of suspended particles, pH levels and the existence of other substances.

Common Challenges in Using Flocculants for Water Treatment

1. Incorrect Flocculant Selection

Selecting the wrong flocculant can result in poor floc formation, leading to inefficient removal of suspended particles. This can be due to various factors such as the type of contaminants, water chemistry, and treatment goals.

Solution: Conduct thorough jar tests and pilot studies to identify the most effective flocculant for the specific water treatment scenario. Engage with flocculant suppliers who can provide technical support and recommendations based on their experience and expertise.

2. Optimal Dosage Determination

Determining the optimal dosage of flocculant is crucial for effective water treatment. Overdosing can lead to excess chemical usage and increased costs, while underdosing may result in insufficient floc formation and poor water quality.

Solution: Implement a systematic approach to dosage determination, including jar tests and real-time monitoring. Automated dosing systems can help in maintaining the correct dosage, ensuring consistent treatment performance.

3. Variations in Water Quality

Fluctuations in water quality, such as changes in pH, temperature, and the concentration of suspended solids, can impact the effectiveness of flocculants. These variations can make it challenging to maintain consistent treatment performance.

Solution: Regularly monitor water quality parameters and adjust the flocculant dosage and type accordingly. Installing online monitoring systems can provide real-time data, enabling prompt adjustments to the treatment process.

4. Mixing and Dispersion

Proper mixing and dispersion of the flocculant in the water are essential for effective floc formation. Inadequate mixing can result in uneven distribution of the flocculant, leading to poor treatment efficiency.

Solution: Design the treatment system to ensure adequate mixing and dispersion. This can include the use of mechanical mixers, static mixers, or specially designed flocculation tanks. Optimize the placement of flocculant injection points to achieve uniform distribution.

5. Environmental and Health Concerns

The use of certain chemical flocculants, especially inorganic ones like aluminum and iron salts, can raise environmental and health concerns. Residual chemicals in treated water can pose risks to aquatic life and human health.

Solution: Explore the use of environmentally friendly flocculants such as natural or biodegradable polymers. Additionally, implement advanced treatment processes to remove any residual flocculants from the treated water before discharge or reuse.

6. Sludge Management

The use of flocculants in water treatment generates sludge, which needs to be properly managed and disposed of. The volume and characteristics of the sludge can vary depending on the type of flocculant used and the treatment process.

Solution: Optimize the flocculant dosage and treatment process to minimize sludge production. Implement efficient sludge dewatering and disposal methods, such as centrifugation, filtration, or digestion, to reduce the environmental impact and costs associated with sludge management.

Advanced Solutions and Innovations in Flocculant Technology

The field of water treatment is continuously evolving, with new technologies and innovations being developed to address the challenges associated with the use of flocculants. Here are some advanced solutions and trends in flocculant technology:

1. Smart Flocculants

Smart flocculants are designed to respond to specific water quality conditions, enhancing their performance under varying treatment scenarios. These flocculants can adapt to changes in pH, temperature, and contaminant levels, ensuring consistent and efficient treatment.

Example: Temperature-responsive flocculants that change their structure at different temperatures, optimizing floc formation and settling rates.

2. Hybrid Flocculants

Hybrid flocculants combine the benefits of inorganic and organic flocculants to achieve superior performance. These flocculants can offer improved floc formation, faster settling rates, and reduce chemical usage.

Example: Combining aluminum salts with polymeric flocculants to enhance charge neutralization and bridging effects.

3. Bio-based Flocculants

Bio-based flocculants are derived from natural sources such as plants, algae, or microbial fermentation. These flocculants are biodegradable and environmentally friendly, making them a sustainable alternative to conventional chemical flocculants.

Example: Chitosan, a natural polymer derived from crustacean shells, has been shown to be an effective and eco-friendly flocculant.

4. Nanotechnology in Flocculants

Nanotechnology is being explored to develop advanced flocculants with enhanced performance characteristics. Nanoparticles can be used to create flocculants with higher surface areas, improved charge density, and increased reactivity.

Example: Nanoparticle-based flocculants that can target specific contaminants and enhance floc formation and settling.

Best Practices for Using Flocculants in Water Treatment

- Conduct Comprehensive Jar Tests: Regularly perform jar tests to evaluate the performance of different flocculants under varying water quality conditions. This helps in selecting the most effective flocculant and optimizing dosage.

- Implement Real-time Monitoring: Use online sensors and monitoring systems to continuously track water quality parameters and adjust flocculant dosage in real-time. This ensures consistent treatment performance and reduces the risk of over- or under-dosing.

- Optimize Mixing and Dispersion: Design the treatment system to ensure proper mixing and dispersion of flocculants. Consider the use of mechanical mixers, static mixers, or specially designed flocculation tanks to achieve uniform distribution.

- Regularly Review and Adjust Treatment Processes: Periodically review and adjust the treatment processes based on changes in water quality, regulatory requirements, and technological advancements. Stay updated with the latest developments in flocculant technology to enhance treatment efficiency.

- Engage with Flocculant Suppliers: Work closely with flocculant suppliers who can provide technical support, recommendations, and customized solutions based on their experience and expertise. This collaboration can help in addressing specific treatment challenges and achieving optimal results.

Conclusion

Flocculants play a vital role in water treatment by facilitating the removal of suspended particles and improving water quality. However, their effective use requires careful consideration of various factors, including flocculant selection, dosage determination, water quality variations, mixing and dispersion, and environmental concerns. By implementing best practices and leveraging advanced solutions and innovations in flocculant technology, water treatment facilities can overcome common challenges and achieve efficient and sustainable treatment outcomes.