Ferric chloride, with the formula FeCl3 is a substance used in various industrial applications such as treating wastewater, etching PCBs and metallurgy. Known for its ability to coagulate ferric chloride plays a role in purifying water by removing substances and contaminants to ensure its safety for both human consumption and industrial purposes. This strong acid is toxic, corrosive, and non-flammable.

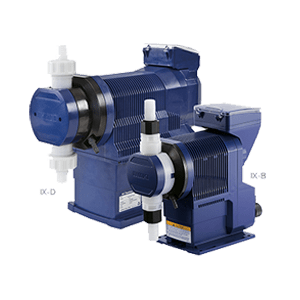

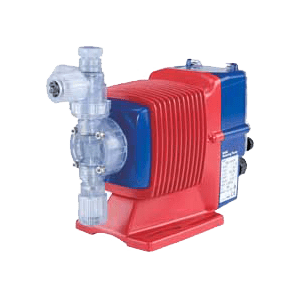

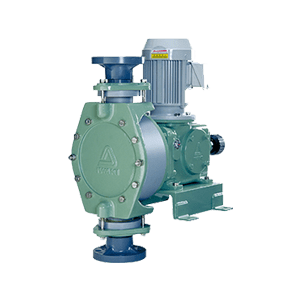

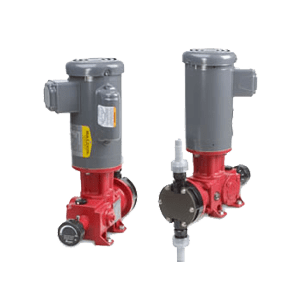

Walchem’s Ferric Chloride Pumps are designed to meet the demanding needs of industrial settings. Walchem pumps set standards for accuracy, reliability and efficiency through years of experience and innovation in chemical dosing technology.

Selecting a Chemical Pump for Ferric Chloride

Selecting a chemical pump for Ferric Chloride is crucial to ensure effective and reliable dosing in industrial settings. Ferric chloride, being an abrasive substance necessitates handling procedures to guarantee its safety and effectiveness. Here are some guidelines on choosing a chemical pump designed specifically for ferric chloride:

Material Compatibility: Given the corrosive nature of ferric chloride particularly towards certain metals and materials it is important to opt for pumps constructed from corrosion resistant materials such as stainless steel, PVC or PVDF (Polyvinylidene Fluoride). These materials offer resistance against the properties of ferric chloride ensuring longevity and dependability.

Seal Selection: Seals play a crucial role in preventing leaks and ensuring the integrity of the pump’s operation when handling ferric chloride. Choose pumps equipped with seals specifically designed for compatibility with corrosive chemicals. EPDM and Viton seals are commonly used for applications involving ferric chloride due to their chemical resistance and durability.

Pump Type: Consider the different types of pumps available for dosing ferric chloride, including diaphragm pumps and air operated pumps. Each type offers unique advantages in terms of dosing accuracy, flow rate, and compatibility with ferric chloride. Diaphragm pumps, for example, provide precise dosing control and are well-suited for handling corrosive chemicals.

Flow Rate and Pressure Requirements: Evaluate your specific flow rate and pressure requirements based on the volume of ferric chloride to be dosed and the operating conditions of your application. Choose a chemical pump capable of delivering the desired flow rate and pressure range while maintaining consistent dosing accuracy.

Chemical Resistance: In addition to ferric chloride, consider any other chemicals or additives present in your process that may interact with the pump materials. Ensure that the pump selected can withstand exposure to all chemicals involved without degradation or compromise in performance.

Industrial Applications Utilizing Ferric Chloride

Ferric chloride finds extensive use across various industries due to its versatile properties and effectiveness in numerous applications. Understanding the diverse range of industries that rely on ferric chloride can help in selecting the right equipment, such as pumps, to meet specific needs. Here are some key industry applications where ferric chloride plays a pivotal role:

Water Treatment: Water treatment facilities utilize ferric chloride as a coagulant in the purification process. It effectively removes impurities, suspended solids, and organic matter from water, making it safe for drinking, industrial processes, and environmental discharge.

Electronics Manufacturing: Ferric chloride is widely used in the production of printed circuit boards (PCBs) as an etchant. It selectively removes copper from the PCB substrate, creating intricate circuit patterns essential for electronic devices’ functionality.

Metal Finishing: Ferric chloride serves as an etchant in metal finishing processes, where it is used to create surface textures, remove oxides, and clean metal surfaces before plating or coating.

Wastewater Treatment: Industries generating wastewater containing heavy metals or organic pollutants utilize ferric chloride as a coagulant or flocculant to precipitate contaminants for easier removal and treatment.

Chemical Manufacturing: Ferric chloride serves as a catalyst or reagent in various chemical synthesis processes, including the production of pharmaceuticals, dyes, pigments, and specialty chemicals.

Steel Production: In metallurgical applications, ferric chloride is used for pickling and surface treatment of steel to remove rust, scale, and impurities, improving surface quality and corrosion resistance.

Advantages of Choosing Ferric Chloride Industrial Pump

Enhanced Process Efficiency: By delivering precise doses of ferric chloride, Walchem pumps optimizes chemical reactions, improving process efficiency and reducing resource consumption.

Cost Savings: With accurate dosing capabilities and low maintenance requirements, Walchem’s Ferric Chloride Pumps help businesses save on chemical expenses and operational costs over time.

Reliability and Consistency: Built to withstand the rigors of industrial environments, our pump ensures reliable performance and consistent dosing, minimizing disruptions to production processes.

Compliance and Safety: With stringent quality control measures and compliance with industry standards, Walchem’s Ferric Chloride Pumps offer peace of mind regarding regulatory requirements and workplace safety.

Tailored Solutions: At Walchem, we understand that every application is unique. That’s why we offer customized solutions tailored to meet the specific needs and challenges of our customers, ensuring optimal performance and satisfaction.