Are you in search of a reliable solution for handling Ethylene Glycol in your industrial processes? Look no further than Walchem Pumps. Our cutting-edge technology and commitment to excellence ensure seamless and efficient handling of Ethylene Glycol, safeguarding your operations and enhancing productivity.

Ethylene Glycol, a vital component in various industries, demands precise handling due to its properties. Whether it’s in HVAC systems, chemical manufacturing, or automotive applications, Ethylene Glycol plays a crucial role. However, its handling requires specialized equipment to ensure safety and efficiency.

Ethylene glycol, chemically expressed as (CH2OH)2, is an alcohol derivative with a high boiling point that is commonly used in cooling operations. It is widely found in manufacturing and industrial situations, where it is particularly advantageous to laser cooling. It is also utilized in filtration systems and in fields as diverse as medicine and automobiles.

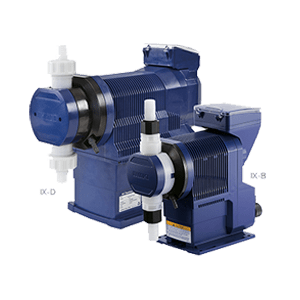

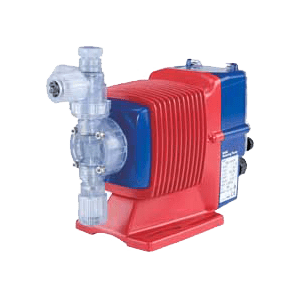

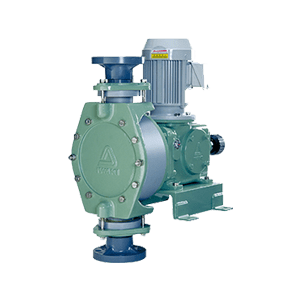

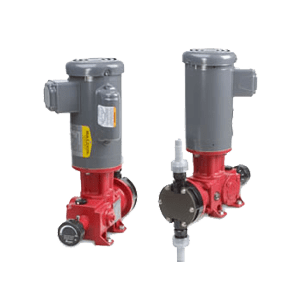

When pumping Ethylene Glycol, consider the following chemical pumps:

What are Common Ethylene Glycol Uses?

Ethylene Glycol finds extensive use across diverse industries, and the need for efficient pumping solutions is paramount. Here are some key applications where Walchem Pumps excel:

HVAC Systems: Ethylene Glycol is commonly used as a heat transfer fluid in HVAC systems, where precise temperature control is essential for optimal performance. Walchem Pumps ensure reliable circulation of Ethylene Glycol, maintaining consistent temperatures and enhancing system efficiency.

Chemical Manufacturing: In chemical manufacturing processes, Ethylene Glycol serves as a vital ingredient in the production of various chemicals, including polyester fibers, antifreeze, and polyester resins. Walchem Pumps offer accurate dosing capabilities, facilitating seamless integration into manufacturing processes.

Automotive Industry: Ethylene Glycol-based antifreeze is widely used in automotive applications to prevent engine overheating and freezing. Walchem Pumps play a crucial role in the production and distribution of automotive antifreeze, ensuring precise blending and delivery for optimal performance.

Cooling Systems: Ethylene Glycol is employed as a coolant in industrial cooling systems, where it helps dissipate heat and maintain equipment operating temperatures. Walchem Pumps provide efficient circulation and transfer of Ethylene Glycol within cooling systems, ensuring reliable heat exchange and equipment longevity.

Food and Beverage Processing: Ethylene Glycol is utilized in food and beverage processing industries for applications such as refrigeration and heating. Walchem Pumps offer hygienic and reliable pumping solutions, adhering to stringent industry standards and ensuring product integrity.

Working Principle of Ethylene Glycol Pump

Walchem Pumps are engineered with a sophisticated working principle designed to handle the challenges posed by Ethylene Glycol. The working principle involves several key components and processes:

Fluid Compatibility: Walchem Pumps are constructed using materials that are compatible with Ethylene Glycol and other corrosive chemicals, ensuring durability and longevity even in harsh operating conditions.

Precision Flow Control: Our pumps feature precise flow control mechanisms, allowing for accurate dosing and transfer of Ethylene Glycol to meet specific application requirements.

Self-Priming Capability: Walchem Pumps are equipped with self-priming capabilities, enabling efficient operation without the need for external priming assistance, thus minimizing downtime and maximizing productivity.

Leak-Proof Design: To ensure safety and reliability, Walchem Pumps are designed with leak-resistant seals and fittings, preventing Ethylene Glycol leakage and minimizing the risk of environmental contamination.

Advanced Monitoring Systems: Our pumps can be incorporated into advanced monitoring systems to continuously track performance parameters such as flow rate, pressure, and temperature, allowing for real-time monitoring and proactive maintenance to prevent downtime.