Intuition-6

Disinfection-Fruit + Vegetable

Walchem controller and disinfection sensor automate peracetic acid application in apple cider production facility, reducing manual input and saving on water and chemical costs. This precise dosing enhances food safety and improves product quality.

Customer | Food Processing

APPLICATION

Peracetic acid is a strong oxidizing agent, and is a very effective biocide and fungicide. It’s ideal for fruit and vegetable process water and is preferred in this application since it can be used in cold and warm water and leaves no toxic residue

In this application, the customer has been using an EZB metering pump to inject Peracetic Acid into wash water that is sprayed on apples through an overhead spray bar. The customer needs to maintain a concentration of 20 – 80 PPM in the wash water. The operators have been adjusting the speed of the pump based on manual titrations. This process is audited routinely for food safety to make sure the correct concentration of Peracetic Acid is present. If it’s too low, the apples need to be washed again. If it’s above 80 PPM, it would be necessary to perform an additional rinse.

PROBLEM

In this application, the customer injects PAA into wash water that is sprayed on apples through an overhead spray bar. The customer needs to maintain a concentration of 20 – 80 PPM in the wash water. The operators have been adjusting the speed of the pump based on manual titrations. This process is audited routinely for food safety to make sure the correct concentration of PAA is present. If it’s too low, the apples need to be washed again. If it’s above 80 PPM, it would be necessary to perform an additional rinse. This highly manual process resulted in wasted time, chemical, and produce.

SOLUTION

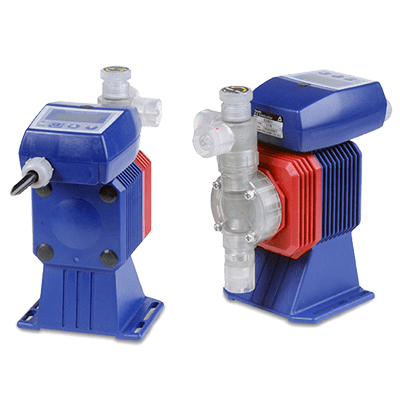

The customer automated the process by installing an Intuition-6 controller with an amperometric Peracetic Acid disinfection sensor.

The sensor monitors PAA concentration in the wash water, while the Intuition-6 controller automates dosing through an EZB pump to maintain 60 PPM of PAA. Level switches in the chemical drums are used to monitor chemical inventories and alarm if the drum gets too low. The Intuition-6 provides the datalogging, remote alarm and communication capability that this customer requires. This increases product safety and efficiency, while reducing spoilage, and ensures that they meet regulatory requirements.

WHERE TO FIND SIMILAR ACCOUNTS

Companies that manufacture disinfection chemicals. Companies that manufacture systems for all stages of the fruit and vegetable industry, irrigation, washing, processing and ice manufacturing. Food and beverage processing/packaging facilities.