Citric acid is an organic acid that has the chemical formula C6H8O7. It occurs naturally in large concentrations in a wide range of fruits and vegetables, most notably the citrus fruit family, which includes lemons, limes, and grapefruits. It can be weighty depending on its concentration and temperature.

Accurate dosage of Citric Acid is crucial to many industrial operations. It is a widely utilized and versatile molecule that finds use in a variety of industries, including food and beverage, medicines, water treatment, and more. However dosing citric acid with accuracy and efficiency has presented numerous obstacles.

Selecting Chemical Pumps for Citric Acid

Choosing the right chemical pumps for citric acid dosing is critical for ensuring seamless operations and optimal performance within industrial settings. Several factors must be carefully considered to select a pump that not only meets the specific requirements of citric acid handling but also aligns with the overall needs of the application:

Material Compatibility: Citric acid, with its acidic properties, demands materials that can withstand corrosion and degradation over time. When selecting a pump, it’s imperative to choose materials that are highly resistant to the corrosive effects of citric acid, such as corrosion-resistant plastics like PVC, PVDF (Polyvinylidene Fluoride) or stainless steel.

Precision and Accuracy: The ability to precisely dose citric acid is paramount in many industrial processes. Therefore, selecting a pump with high accuracy and precision control features ensures consistent and reliable dosing, minimizing waste and optimizing efficiency.

Viscosity Considerations: Citric acid solutions can vary significantly in viscosity, depending on factors such as concentration and temperature. A pump that can handle a wide range of viscosities ensures smooth and uninterrupted operation, even when dealing with more viscous citric acid formulations.

Ease of Maintenance: Regular maintenance is essential to keep industrial processes running smoothly. Choosing a pump with easy maintenance features, such as quick disassembly for cleaning and servicing, can help minimize downtime and ensure maximum uptime for your operations.

Integration with Control Systems: In many industrial applications, automated control systems govern the dosing of citric acid. Selecting a pump that seamlessly integrates with existing control systems, or offers advanced control options such as remote monitoring and programmable dosing profiles, enhances overall process efficiency and management.

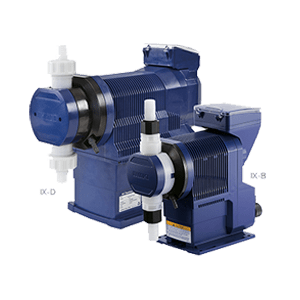

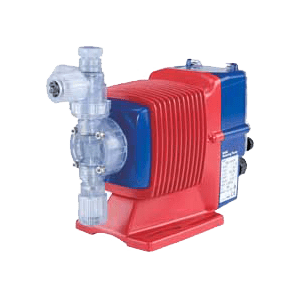

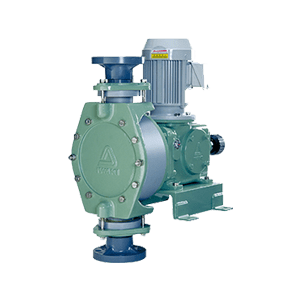

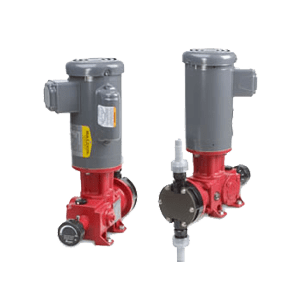

The following chemical pumps are a good place to start looking when pumping the chemical Citric Acid:

Common Applications of Citric Acid Industrial Pump

The applications of Walchem Citric Acid Pumps are virtually limitless, spanning across a wide range of industries and processes:

Food and Beverage: In the food and beverage industry, citric acid plays a pivotal role in enhancing flavors, preserving freshness, and regulating acidity. Citric Acid industrial pumps ensures precise dosing, enabling manufacturers to achieve consistent product quality while optimizing production efficiency. From soft drinks and fruit juices to sauces, jams, and confectionery, our pumps facilitate precise citric acid dosing, ensuring the perfect balance of taste and preservation.

Water Treatment: Effective water treatment relies on precise control of pH levels, scale formation, and microbial growth. Citric acid serves as a vital component in water treatment processes, where it helps to regulate pH, inhibit scale formation, and enhance the efficacy of disinfection treatments.

Pharmaceuticals: Citric acid finds widespread use in pharmaceutical formulations, where it serves as a chelating agent, acidulant, and pH regulator. From tablet coatings and liquid suspensions to intravenous solutions and nasal sprays, citric acid plays a crucial role in ensuring the stability, solubility, and bioavailability of pharmaceutical products.

Chemical Processing: Citric acid’s chelating and buffering properties make it indispensable in various chemical processes, including metal cleaning, descaling, and industrial synthesis. Whether used as a cleaning agent in metal finishing or as a catalyst in organic synthesis, citric acid dosing ensures consistent results and process optimization in chemical processing applications.

Industrial Cleaning: Citric acid’s ability to dissolve mineral deposits, rust, and scale makes it a valuable tool in industrial cleaning applications. From equipment descaling and surface cleaning to boiler treatment and rust removal, citric acid offers a safe, effective, and environmentally friendly alternative to harsh chemical cleaners.

Key Features and Benefits of Citric Acid Chemical Pump

Walchem chemical pumps are engineered to address these challenges head-on, offering a comprehensive solution for precise citric acid dosing in a wide range of industrial applications. Whether you’re looking to enhance food and beverage production, optimize water treatment processes, or streamline pharmaceutical manufacturing, our pump delivers unparalleled performance and reliability. Here are some key features of chemical pumps offered by Walchem for Citric Acid dosing.

Precision Dosing: Walchem Citric Acid Chemical pumps boasts exceptional accuracy, ensuring precise dosing of citric acid into your industrial processes. With customizable flow rates and dosage settings, you can fine-tune your operations with unmatched precision, reducing waste and maximizing efficiency.

Versatility: Our pumps are designed to accommodate various concentrations and viscosities of citric acid, making it suitable for a diverse array of applications. From dilute solutions to highly concentrated formulations, Walchem Citric Acid chemical pumps handle it all with ease, offering unparalleled versatility for your industrial needs.

Robust Construction: Built to withstand the rigors of industrial environments, Walchem Citric Acid chemical pumps feature a rugged construction that ensures durability and longevity. With corrosion-resistant materials and robust components, you can rely on our pump to deliver consistent performance day in and day out, even in the harshest conditions.

Advanced Technology: Equipped with cutting-edge technology, including precision sensors, intelligent monitoring systems, and remote connectivity options, our Citric Acid Pumps represents the forefront of industrial innovation. Stay informed and in control of your processes like never before, with real-time data insights and remote management capabilities at your fingertips.

Why Choose Walchem for Citric Acid Dosing?

When you choose the Walchem Pumps, you’re not just investing in a piece of equipment—you’re investing in a partner committed to your success. With decades of experience in providing innovative solutions to industries worldwide, Walchem stands as a trusted leader in industrial equipment and automation.

- Reliability: Count on us for reliable performance, robust construction, and unparalleled durability.

- Expert Support: Our team of experts is dedicated to assisting you every step of the way, from initial consultation to ongoing support and maintenance.

- Custom Solutions: We understand that every application is unique. That’s why we offer customizable solutions tailored to your specific requirements and challenges.

- Commitment to Excellence: At Walchem, we’re driven by a relentless pursuit of excellence. We continuously strive to push the boundaries of innovation and set new standards of quality and reliability.