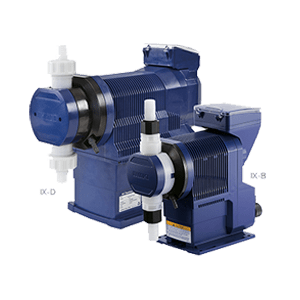

In industrial processes, the handling of chemical substances demands unparalleled precision and reliability. Acetic acid, a fundamental chemical compound with a wide array of industrial applications, poses unique challenges due to its corrosive nature and propensity for causing material degradation. Walchem’s Acetic Acid Pumps are a pinnacle of engineering design, meticulously manufactured to conquer the complexities associated with the dosing of this vital chemical compound.

Selecting an Acetic Acid Industrial Pump

Acetic acid, also known as ethanoic acid, is a crucial chemical compound utilized in various industries worldwide. From the production of solvents, plastics, and pharmaceuticals to its role as a key component in food preservation and flavoring, acetic acid plays a multifaceted role in modern manufacturing processes. As a highly corrosive substance with the potential to damage equipment and compromise operational integrity, the safe and efficient handling of acetic acid is paramount. Walchem understands the intricacies of this chemical compound and has engineered a solution that not only meets but exceeds industry standards – Walchem Acetic Acid Pumps.

Selecting the right Acetic Acid industrial pump for handling acetic acid is a critical decision that can significantly impact the efficiency, safety, and reliability of your operations. With various options available in the market, it’s essential to consider key factors to ensure you make an informed choice that aligns with your specific requirements and industry standards. Here’s why Walchem Acetic Acid Pumps stands out as the premier choice for industrial applications:

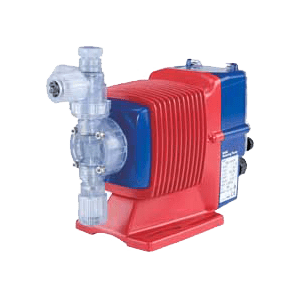

Chemical Compatibility: Acetic acid’s corrosive properties necessitate a pump specifically engineered to withstand its aggressive nature. Walchem’s Acetic Acid Industrial pumps are constructed from high-quality materials resistant to corrosion, ensuring long-term reliability and minimal maintenance.

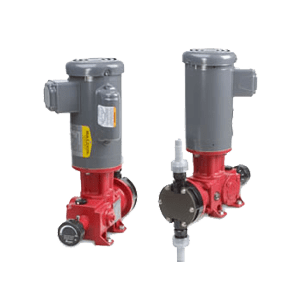

Safety Features: The safe handling of acetic acid is paramount in industrial environments. Walchem pumps are equipped with advanced safety features such as leak detection systems and overload protection mechanisms, prioritizing the well-being of your workforce and facility.

Performance and Efficiency: Walchem’s Acetic Acid industrial pumps deliver unparalleled performance and efficiency when dosing for specific applications. With customizable configurations and precise engineering, our pumps ensures optimal performance and minimal energy consumption, maximizing productivity and cost-effectiveness.

Seamless Integration: Integration into existing industrial setups should be seamless to minimize downtime and operational disruptions. Walchem’s Acetic Acid Industrial pumps are designed for easy installation and compatibility with a wide range of systems, ensuring a smooth transition and uninterrupted operations.

Tailored Solutions: Every industrial process is unique, and one size does not fit all. Walchem offers tailored solutions customized to meet your specific requirements, ensuring optimal performance and operational efficiency in any industrial setting.

Commitment to Quality and Sustainability: Walchem is committed to delivering high-quality, sustainable solutions that meet and exceed industry standards. Each Acetic Acid Pump undergoes rigorous testing and quality assurance processes, ensuring compliance and peace of mind for our customers.

Industries and Applications Handle Acetic Acid

Acetic acid, with its versatile properties, finds applications across a diverse range of industries, each with unique requirements and challenges. Understanding the specific industries and applications that utilize acetic acid is essential for selecting the right pumping solution. Here’s a closer look at some of the key industries and applications where acetic acid plays a pivotal role:

Chemical Manufacturing: Acetic acid serves as a fundamental building block in the chemical manufacturing industry, where it is used in the production of various chemicals, including acetate esters, vinyl acetate monomer, and acetic anhydride. Chemical manufacturers rely on acetic acid chemical pumps for precise dosing and transferring of this essential compound in their production processes.

Food and Beverage Industry: In the food and beverage industry, acetic acid is commonly employed as a food additive, flavoring agent, and preservative. It is a primary component of vinegar, imparting its characteristic sour taste to a wide range of culinary products. Acetic acid chemical pumps are utilized for the precise metering and blending of vinegar solutions in food processing facilities.

Pharmaceuticals and Healthcare: Acetic acid finds applications in pharmaceutical formulations, where it serves as a solvent, pH adjuster, and chemical intermediate in the synthesis of various drugs and pharmaceutical compounds. Pharmaceutical manufacturers rely on acetic acid pumps for accurate dosing and blending of solutions in their production processes.

Textile Industry: In the textile industry, acetic acid is used in the production of cellulose acetate fibers, commonly known as acetate fibers. These fibers are utilized in the manufacture of textiles, including clothing, upholstery, and industrial fabrics. Acetic acid chemical pumps play a crucial role in the precise delivery and mixing of acetic acid solutions in textile processing plants.

Petrochemical Industry: Acetic acid serves as a feedstock in the petrochemical industry, where it undergoes various chemical reactions to produce other compounds, such as ethylene and vinyl acetate. Petrochemical refineries utilize acetic acid chemical pumps for the safe and efficient handling of this chemical compound in their production processes.

Industrial Cleaning and Surface Treatment: Due to its solvent properties, acetic acid is utilized in industrial cleaning products and surface treatment formulations. It is effective in removing mineral deposits, rust stains, and scale buildup from various surfaces. Acetic acid pumps are essential for the accurate dispensing and mixing of cleaning solutions in industrial cleaning applications.

Considerations for Pumping Acetic Acid

Selecting the right pump for handling acetic acid involves careful consideration of several factors to ensure efficient and safe operations. Acetic acid’s corrosive nature and specific handling requirements make it imperative to choose a pump that can withstand its properties while delivering precise and reliable performance. Here are key considerations to keep in mind when selecting an acetic acid pump:

Material Compatibility: Acetic acid is highly corrosive, especially at higher concentrations or temperatures. Therefore, it’s crucial to choose a pump constructed from materials that are compatible with acetic acid, such as stainless steel, Hastelloy, or PVDF (Polyvinylidene fluoride). Walchem’s Acetic Acid chemical pumps are engineered with materials specifically selected for their resistance to corrosion, ensuring long-term durability and reliability.

Seal Selection: Seals are critical components in preventing leaks and ensuring the integrity of the pumping system when handling acetic acid. Selecting seals made from compatible materials, such as fluorocarbon elastomers (e.g., Viton), ensures optimal performance and longevity in corrosive environments. Walchem’s Acetic Acid chemical Pumps ares equipped with high-quality seals designed to withstand the challenges posed by acetic acid, providing leak-free operation and enhanced safety.

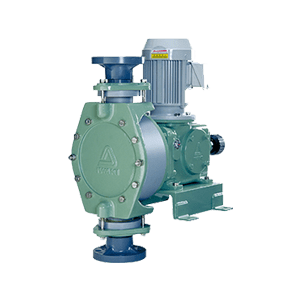

Pump Design and Configuration: The design and configuration of the pump play a significant role in its performance and efficiency when handling acetic acid. Factors such as flow rate, pressure requirements, and suction conditions must be carefully evaluated to select the appropriate pump type and size for the application.

Safety Features: Safety should always be a top priority when handling acetic acid. Look for pumps equipped with advanced safety features, such as leak detection systems, overload protection mechanisms, and emergency shut-off valves, to mitigate risks and ensure the well-being of personnel and equipment. Walchem’s Acetic Acid chemical pumps are designed with built-in safety features to provide peace of mind and prevent potential accidents or hazards in industrial environments.

Maintenance and Serviceability: Regular maintenance is essential to keep the pump operating at peak performance and extend its service life, especially when handling corrosive substances like acetic acid. Choose a pump that is easy to maintain and service, with accessible components and minimal downtime requirements. Walchem’s Acetic Acid chemical pumps are designed for simple maintenance procedures, allowing for quick and hassle-free servicing to minimize disruptions to your operations.